Relax – all runs smoothly!

HELANTEC Production control

The economic success of modern insulated glass production significantly depends on 3 factors:

-

uniform, assured quality

-

optimal, systematic use of all resources (time, material, equipment availability)

-

compliance with statutory regulations (CE mark, EN 1279, documentation, etc.)

HELANTEC offers systems for quality assurance and quality verification. An assured verification is superior to “claim or assume” in every situation.

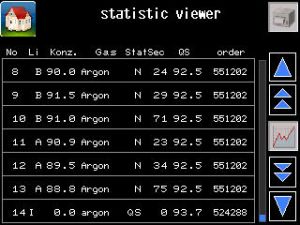

The IPC (integrated production control) visualises the filling process in real time. At a glance you know whether the filling process is being executed correctly and economically. In addition, all filling processes, i.e. each IG unit, is documented – in an automated procedure, without additional effort.

For gas filling presses, with the IGM/IPA process monitor, consisting of ISO-GAS-METER (IGM) and ISO-PRESS-ANALYSER (IPA), we offer you a gas filling process monitor. Among other things, it monitors and visualises the gas filling process of each manufactured IG unit, signals deviations in concentration, gas consumption, and documents the filling process. It is 100% process monitoring. Thus deviations to the normal production and errors are detected immediately and can be directly resolved. There are no comparable systems on the market! Only HELANTEC makes gas visible.

Although trust, confidence, and hope in a successful production do indeed represent the most comfortable solution, it is far too little for modern industrial manufacturing and thus the corporate risk is too high.

Integrated Process Control (IPC)

Quality assurance and quality verification are of central significance for a company. In this regard, with the HELANTEC Integrated Process Control (IPC) you can sit back and relax.

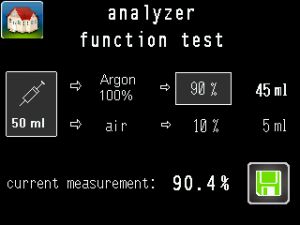

The IPC visualises the filling process in real time. At a glance you know whether the filling process is being executed correctly and economically. In addition, all filling processes, i.e. each IG unit, is documented – in an automated procedure, without additional effort.

Versatile interfaces enable the connection of a label printer, barcode scanner or network integration. Thus all units can be uniquely identified and marked – traceability is easily possible.

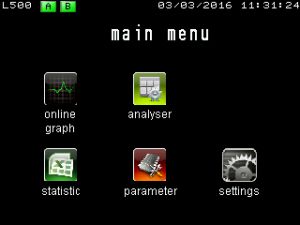

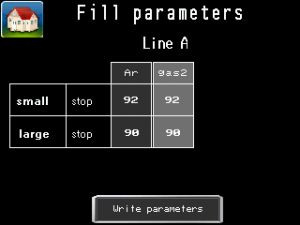

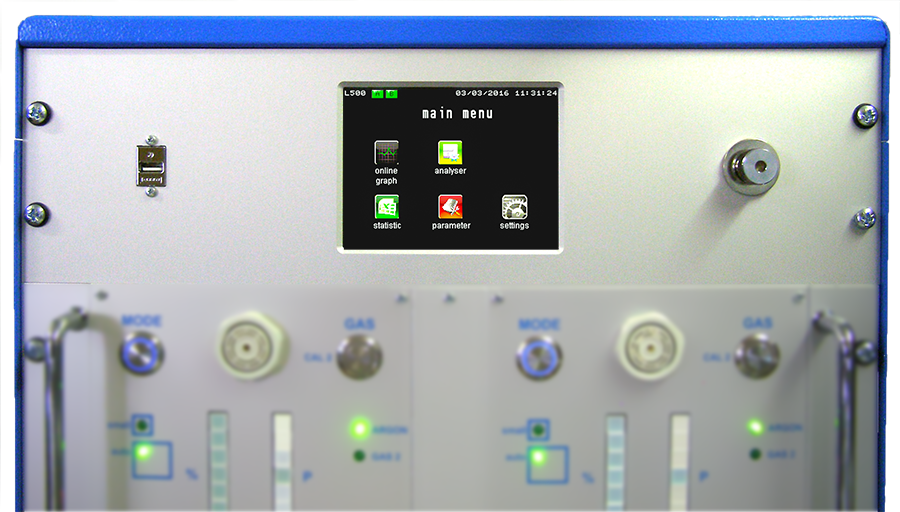

The IPC can be integrated in the RAPIDE L500 and RAPIDE L900 gas filling systems, as an option. Various filling parameters can be set individually and changed at any time; this means that your gas filling system can be easily adapted to changing requirements.

An integrated gas analyser (type ISO-GAS-Control) is available for quality control, as an option. With the gas analyser the recorded measured values for quality control can be directly assigned to each IG unit, this means that the quality control results are directly compared with the production control results and documented. All recorded data can be analysed directly on the PC and compared with reference data as an evaluation aid.

With the integrated modem a diagnosis can be quickly and specifically executed via remote maintenance. There is nothing faster, easier, or more cost-effective.

This system is unique for manual gas filling systems. There is no comparable system on the market. And only HELANTEC makes gas visible.

The IPC is a worthwhile investment and is (almost) indispensable for companies with a rigorous quality-consciousness and proactive cost-consciousness.

IGM / IPA

Process monitoring of the gas filling function for gas filling presses

The economic success of modern insulated glass production significantly depends on 3 factors:

- uniform, assured quality

- optimal, systematic use of all resources (time, material, equipment availability)

- compliance with statutory regulations (CE mark, EN 1279, documentation, etc.)

Currently, at least 1% of production must be checked and documented relative to gas concentration. At the same time however the producer must guarantee the assured characteristic for each individual product (100%).

In this regard, delimitation of risk is of central significance. Faulty products often cause undesired economic consequences and not infrequently result in sustained damage to the company’s image.

It is precisely at this point that present handling differs from the requirements of the market. This is where HELANTEC offers you the perfect solution.

Only HELANTEC makes it possible to visualise, monitor and document the gas filling process for gas filling presses.

The system, consisting of ISO-GAS-METER (IGM) and ISO-PRESS-ANALYSER (IPA).

- monitors and visualises

- the gas filling process of each manufactured IG unit

- the gas type

- distribution of the gas during the filling process - signals

- direct deviations from the setpoint (early warning)

- deviations in consumption - documents the filling procedure

- presents a diagnostics aid (visualisation)

It is 100% process monitoring; errors are detected immediately and can be directly resolved.

Thus an automated QA system that reliably monitors the gas filling process is available to the user. Through the connection to a central database, if there is a complaint, a verification of quality can easily be provided.

Due to the increasing manufacturing automation the HELANTEC process monitor is indispensable for precise monitoring and documentation of the individual manufacturing steps. It considerably facilitates your management tasks.

Although trust, confidence, and hope in a successful production indeed represent the most comfortable solution, it is not sufficient for modern industrial manufacturing.

SEALANT INSPECTOR

Process monitoring for sealing systems with 2-component sealants.

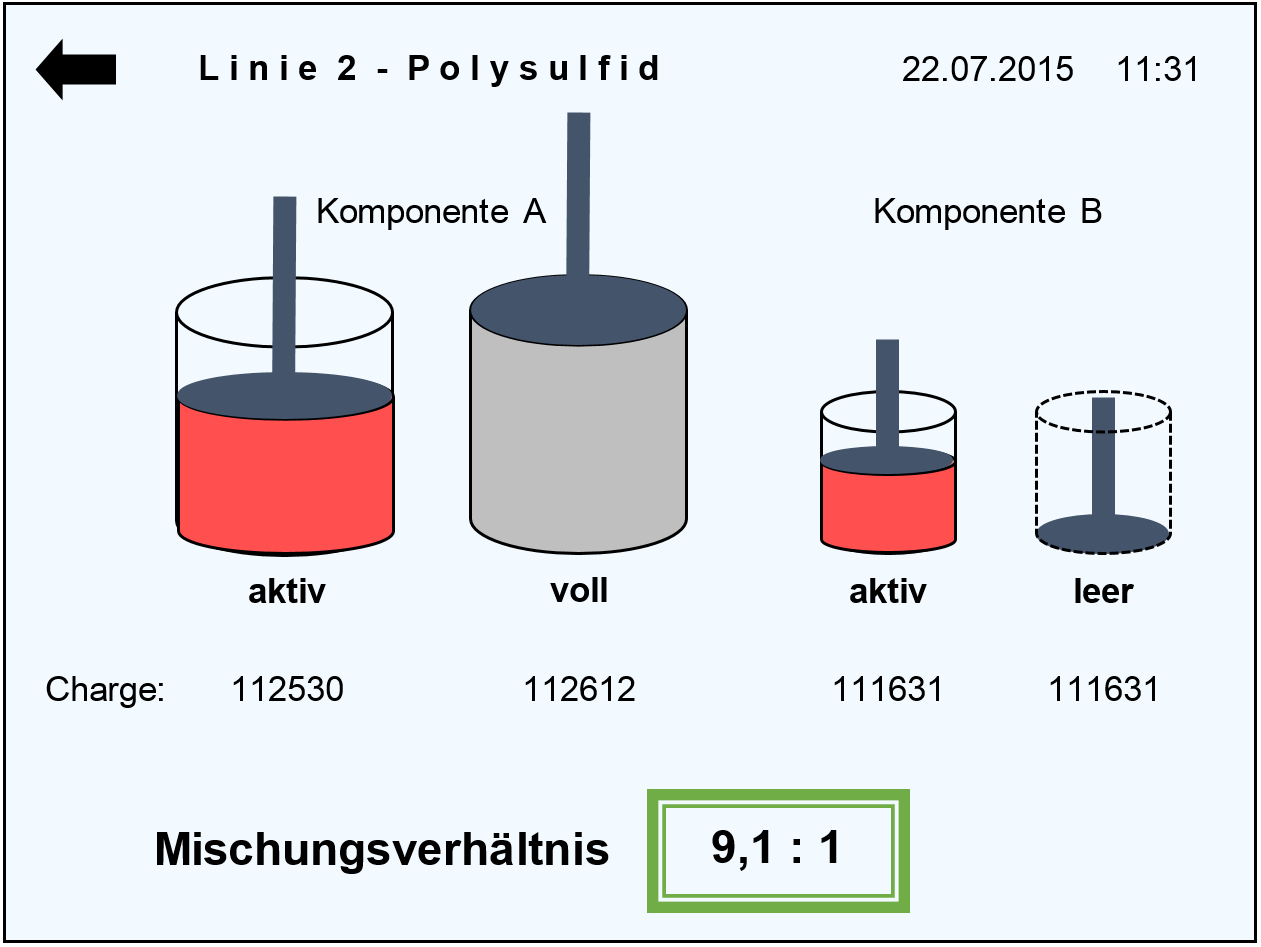

The processing of 2-component sealants requires a certain quality inspection of the mixing ratio. Instead of complex and time-consuming procedures, the SEALANT INSPECTOR monitors continuously the mixing ratio. Moreover, it informs immediately about any deviation.

This ensures that the requirements of the sealant manufacturer are reached. Therefore, the IG manufacturer knows that the mixed sealant fulfils the specified guaranteed properties (e.g. tensile strength, adhesion etc.). Variations in the mixture would have both short- and long-term consequences (for example, a non-hardening edge seal, missing tightness, or reduced adhesion properties).

Therefore, the sealant manufacturers require strict quality controls. They user has to check the mixing quality and pot life (snap time) as well as the mixing ratio. For this purpose, the individual components are filled simultaneously via exhaust valves to the mixing station in separate vessels. The mixing ratio is then determined by weighing the respective mass. This procedure is repeated three times and an average is calculated. If this is out of tolerance, the IG production has to stop and the mixing station has to be re-adjusted again. This procedure has to be performed after each re-start of the production line and after each barrel change. This makes it very complex and expensive.

By using the SEALANT INSPECTOR, this expensive and time-consuming control of the mixing ratio is not necessary! Because the system monitors and controls continuously the mixing ratio and informs the user immediately if deviations occur. Thus the operator can react immediately, even before a faulty IG unit is produced. All measurements are automatically documented by the device.

The recorded data can be accessed directly from the network. All data can be transferred to the company database. The SEALANT INSPECTOR can be installed at all usual barrel pumps, both for manual sealing as well as for sealing robot. The IG production has to be interrupted only briefly.